We hinted at the end of our blog article – 2023 Trial: Impacts of Soil Fumigation of Tobacco – that we also did trials on sweetpotatoes that compared mixtures on Enterolobii nematode control and dual applications on seed production. Track number 1: why high why nematodes? Answered further in this article. Track number 2: why did we get late season resurgence?

In this blog we will go into more detail on those trials, the outcomes, and the implications.

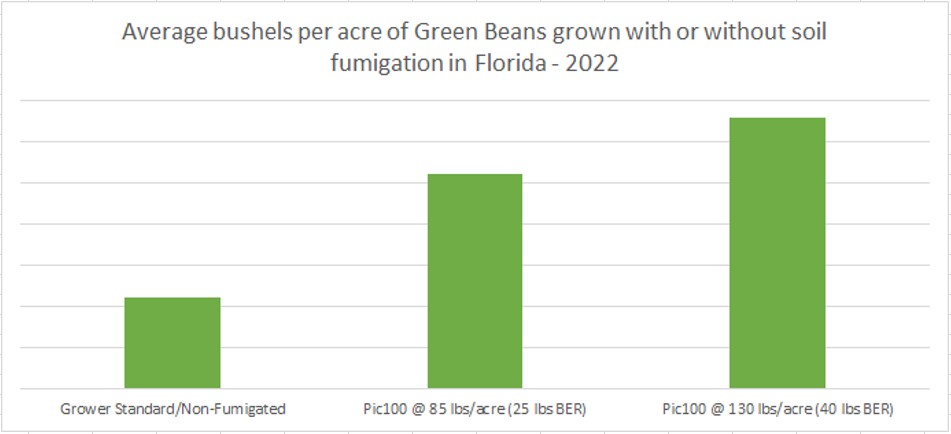

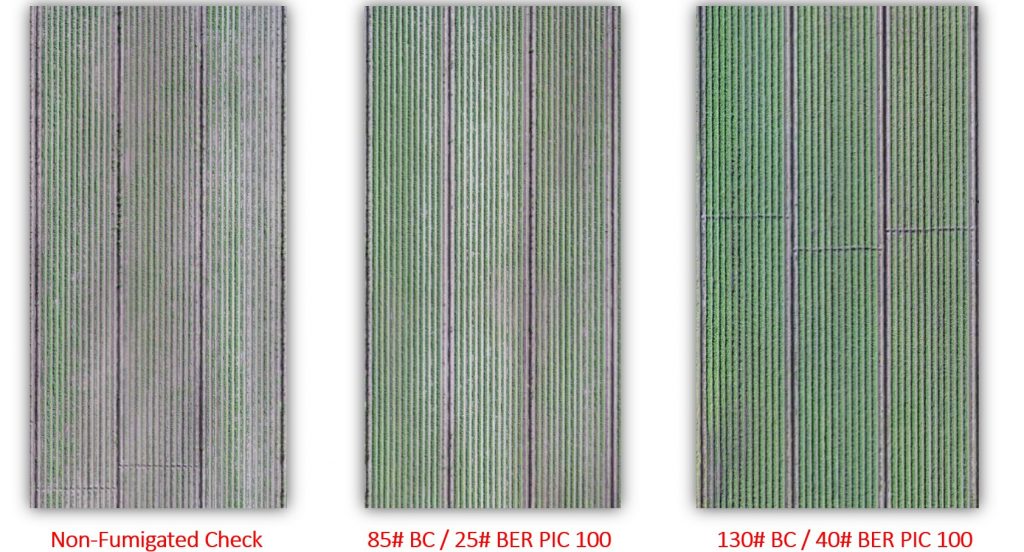

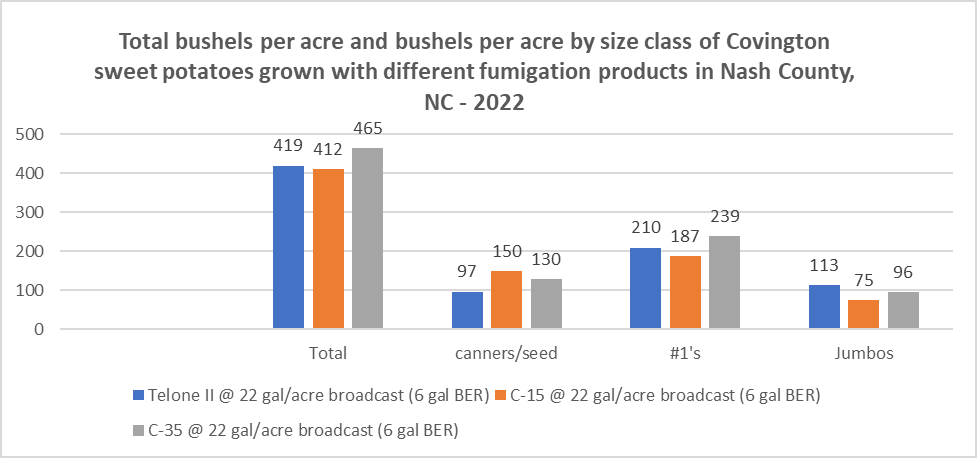

In the Summer/Fall of 2022 TriEst Ag Group did a mixture study that focused on Enterolobii in Nash County, NC. The trial evaluated the use of TELONE™ by Teleos soil fumigant, TELONE™ C-15 by Teleos, and TELONE™ C-35 by Teleos at 6 GPA (22 GPA broadcast) shank applied in-row 14” deep with 10” of stack. The row was re-shaped to 5-8” in front of planter. The field had a heavy Enterolobii (Guava Root Knot Nematode or GRKN) pressure.

We fumigated the field May 11, 2022, the field was planted June 14, 2022, and harvested October 24th, 2022.

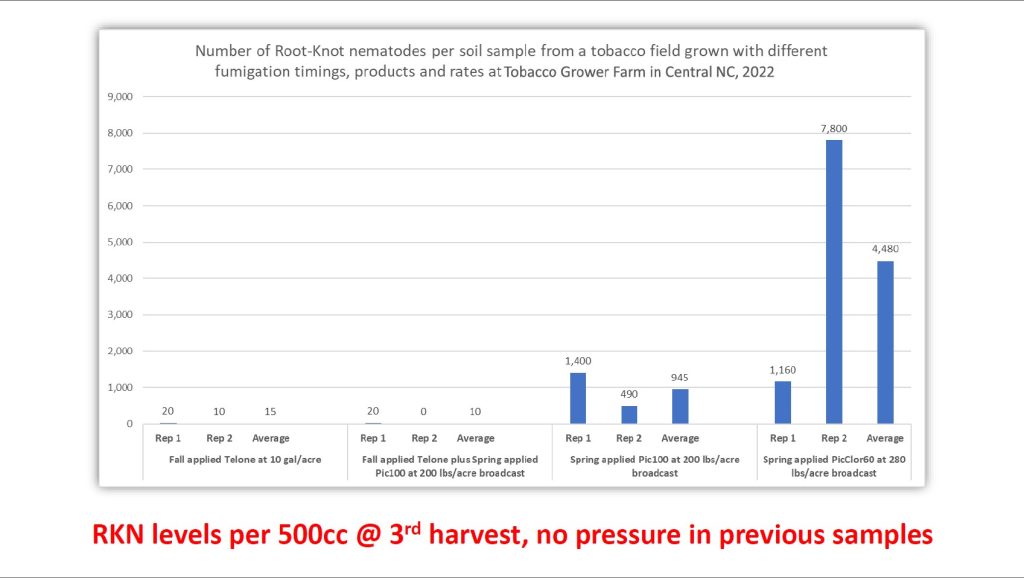

This chart shows that Guava Root Knot Nematode (GRKN) resurged in all 3 plots. Damage was observed in all plots as well, but was worst in TELONE™ C-35, which would be expected from the treatment with the least amount of TELONE™ being applied.

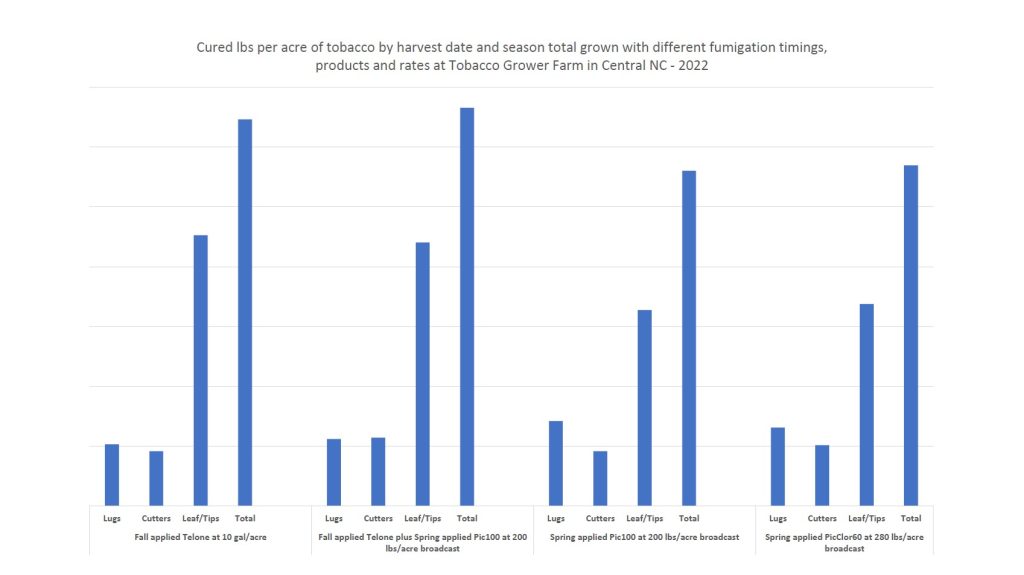

Despite TELONE™ C-35 having the worst GRKN levels and damage it still provided the highest yields and the best crop throw showing a clear benefit to having Chloropicrin in the system. For this growing region that is focused on table stock production, bushes of #1’s per acre is critical.

The results of this trial left us with a significant observation and question, why did we have the highest yield in a treatment with the highest volume of nematodes at seasons end?

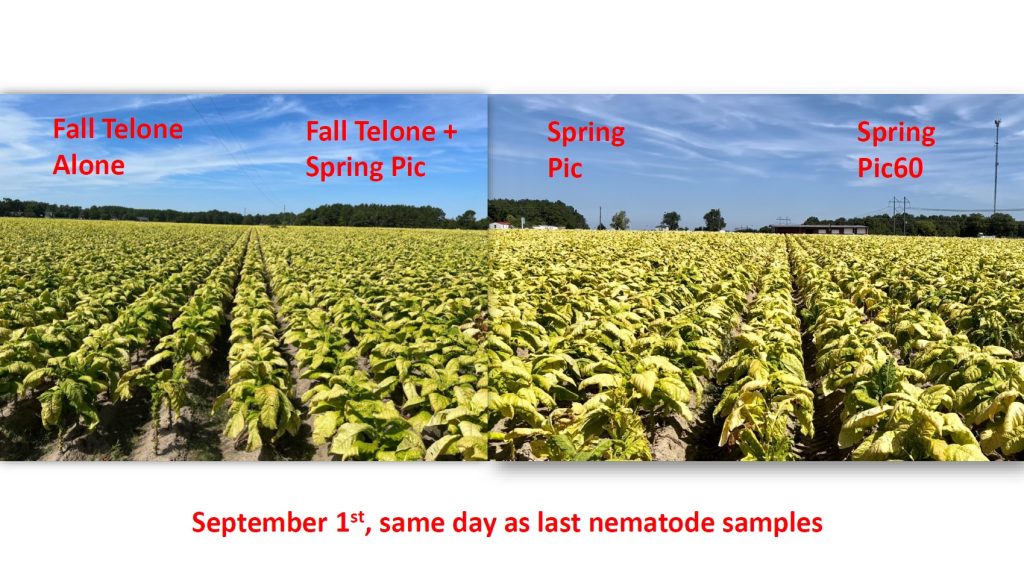

Nematode pressures rose in the last 30 days of the crop, even with very good suppression of the pest after each treatment application. Why did we see a late season resurgence of nematodes? How mobile is GRKN and are they moving from untreated areas back into the root zone? Would a deeper application work? Would a wider area of application make a difference?

While we answer the question of why did we have the highest yield in a treatment with the highest volume of nematodes at season’s end in this article the remaining questions this trial spurred we will answer in a future article on another field trial from 2023.

Back to the impact of chloropicrin…

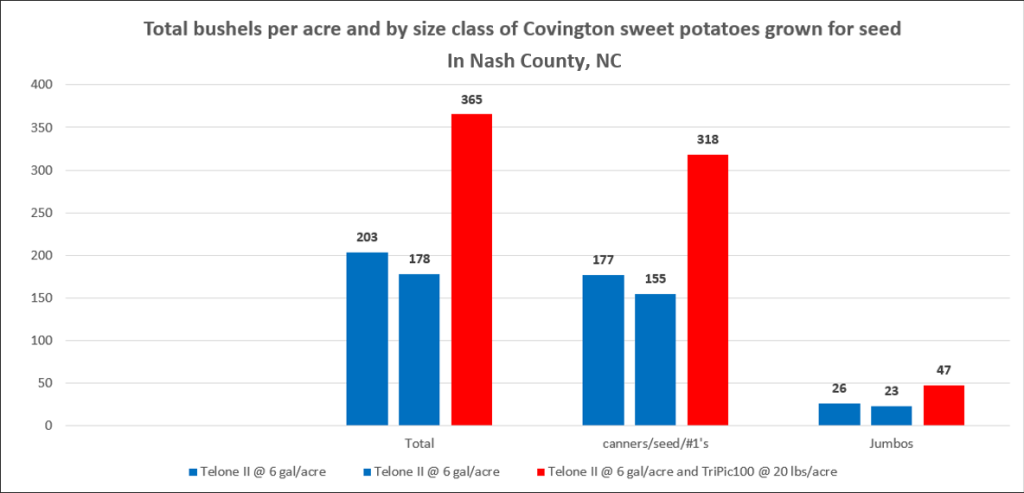

The following summer/fall of 2023 we decided to look at TELONE™ and TELONE™ with PIC applied in a dual level application to see if we could build off of what we learned in the 2022 trial.

The trail took place in Nash County, NC again, but this trial purposefully had low root knot nematode pressure. The primary goal was to see the impact of Chloropicrin on the crop and build off of what we learned in 2022.

The sweet potato crop in this trial was grown for seed, where growers are targeting heavier tuber sets and smaller size profiles overall, which is what we saw in the 2022 trial harvest.

We fumigated 6/3/2023 with TELONE™ at 6 GPA in-row (22 gallons broadcast) and TELONE™ at 6 GPA in-row plus 20lbs PIC100 (75lbs broadcast) in a dual application 8” PIC and 14” TELONE™. Everything was shank applied in-row with a ripper bedder at 14” with 10” of stack. The row as reshaped to 5-8” in front of the planter.

The field was planted on 6/23/2023 and the crop was harvested on 10/20/2023.

The conclusion from this trial was that the addition of a low dose of Chloropicrin (75lbs Broadcast/20lbs BER) increased the tuber set. This resulted in a higher yield and smaller size profile overall. This is a big advantage for seed growers. We feel that getting the Chloropicrin dose as close to the where the root system will be (6-8” beneath final planting depth) is important. For nematode management, TELONE™ should be applied 12-16” deep to treat the highest volume of soil possible, which is why we looked at dual application as opposed to a blend with both products being applied down deep.

In conclusion, the key takeaways from these trials would be that higher sweet potato yields can be achieved when a low dose of Chloropicrin is used to increase set. TELONE™ is critical for nematode management and depth of application is important in regards to location of the pest in the soil profile. Dual level application with Chloropicrin applied in the root zone and TELONE™ applied beneath the root zone increases tuber set while also maximizing nematode management.

Remember to subscribe so that you don’t miss our future blog article on our work in sweetpotatoes that will answer the questions of why did we see a late season resurgence of nematodes? How mobile is GRKN and are they moving from untreated areas back into the root zone? Would a deeper application work? Would a wider area of application make a difference?

To learn more now or talk to a representative about seeing what Chloropicrin can do in your field Contact Us Here.