Reduced tillage systems have become a focal point throughout agriculture in recent years. The logic behind incorporating tillage reduction is clear, as there are many benefits associated for both the farmer and the land they tend.

- Reduced soil erosion

- Preserve soil structure

- Lessen impact on soil microbiome

- Reduced production costs

- Better water management

With all that being said, tillage is also a critical component in the production system of many crops, especially potato. Two things can be right at one time, this is true of the importance of tillage in agriculture and the advantages of reduced tillage systems. It is important to remember that standard systems developed over time for a reason, because they were needed and effective. Conventional tillage provides:

- improved aeriation

- weed suppression

- Incorporation of fertility and pest control products

- Hard-pan improvements with deep tillage

- Seedbed preparation

As with any decisions we make in agriculture, there is a push and pull relationship to anything we do. The intent should be to maximize advantages while limiting the disadvantages and result on a net gain in the end. A friend and colleague of mine in agriculture compared this to counting calories while looking at a menu in a restaurant. You can have tillage, but it comes at a cost. Portion sizes matter and if we want a large portion, what are you willing to give up to stay under the threshold?

A larger sector of agricultural producers are introducing reduced tillage into their cultural systems and TriEst Ag Group recognized the need to investigate the use of Chloropicrin in this manner. It’s important that we innovate and evolve alongside our customer base. Much like conventional tillage systems being a standard for a reason, there are principles to fumigation that are required by label to ensure proper handling and efficacy.

- Soil properly prepared in seedbed condition and free of clods at time of application

- Soil moisture at 50% or greater and soil temperatures less than 90 F at the time and depth of application

- Application depth must be 12” from the nearest air to soil interface

- Field residue must be managed, little crop residue on soil surface that can’t impact soil seal

- For soil sealing, soil must be uniformly mixed to at least a depth of 3 inches to eliminate the chisel trace. Following elimination of the chisel trace, the soil surface must be compacted or pressed to complete the seal

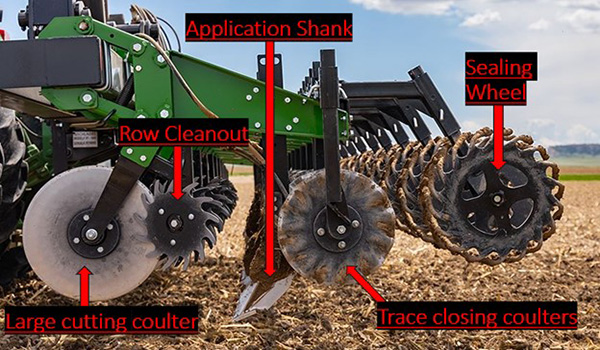

Similar to our customers, it’s quite the challenge to figure out how to accomplish reducing tillage and maintaining efficacy for growing a productive crop. Over the past three years, TriEst Ag Group has worked diligently with grower cooperators to develop equipment application options to achieve these goals. The result of these efforts is strip-till fumigation. As the name implies, with this method we are only applying tillage in the “strip” or area where fumigant is specifically being applied in the row. The equipment used for this process is really broken down into five steps:

- Large straight edge coulter (cutting coulter) that cuts through field debris in the center of the row

- Notched coulter (row cleanout) that grabs the cut field debris and throws it out of the strip

- Shank that is providing deep tillage to reduce compaction in the root zone and applying the fumigant product

- Set of wavy coulters (closing discs) that are pinching the soil behind the shank to shut down the chisel trace and eliminate any chimney effect

- Compacting wheel (several options pending the desired final surface) is sealing the tilled area after the shank trace has been closed

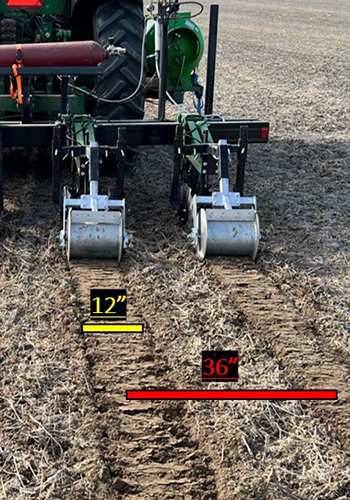

A lot of our development work has been focused on potato growing systems, so we will use that as an example. Potato is typically grown on 34″-40” row centers and our tillage/application strip is 12” wide, which encompasses the area the potatoes will be grown in. If we use a 36” row center example, 12” divided into 36” equals 33%, representing the percentage of land that is tilled. This effectively reduces tillage by 67% for our fumigation application.

The tillage reduction is magnified several times over when you consider the preparation tillage passes prior to the application that are also removed. The number of passes and costs associated are on a case-by-case basis, as all farming operations have different procedures. The previous crop is also very important in this discussion, due to the level of difficulty associated with heavier residue. A few good examples from potato growing systems would be:

- Prior crop being soybeans or a small grain – one disc pass prior to application pass

- Prior crop being corn – one disc-ripper pass followed by two disc passes prior to application pass

The impacts can be quite significant when you consider the cost and time savings of removing pre-tillage passes out of a production system. An added benefit to no pre-tillage is conserving moisture. Tillage opens the land to moisture loss and could impact fumigation viability, resulting in more lost time. Using an application with no pre-tillage requirement insulates that moisture and allows for a much longer application window in the Fall or Spring. Another key consideration pending the crop being grown is any tillage that is done after fumigation that may move or bring in untreated soil into the application strip. Like pre-tillage, there are many considerations here based on specific operations, but it must be accounted for to ensure efficacy and a quality end result.

In our next article, we will go through trial results in several geographies across the potato production regions in the United States and look at how strip-till fumigation performed when competing head-to-head against traditional grower standard application practices.

Until then you may want to watch some of our videos on equipment or harvest trials. Or you can reach out to talk to your local sales representative here.