Water, fertilizer, and energy are some of the most expensive inputs in farming today. At the same time, growers are under pressure to maximize yields while protecting resources. A drip irrigation system designed with smart irrigation technology meets these challenges head-on.

When built with irrigation design software used by qualified engineers, installed by trained automation professionals, and supported by quality components, drip irrigation becomes more than a watering method, it’s a complete management tool that pays back every season.

How Drip Irrigation Works

Unlike flood or sprinkler irrigation, drip irrigation delivers water directly to the root zone through a network of mainlines, submains, dripline, and emitters.

Key components include:

- Mainline and submains – move water efficiently from the pump to the field.

- Dripline or drip tape – applies water drop by drop at the plant row.

- Pressure regulation and valves – maintain uniform delivery across the system.

- Filtration – keeps water clean to prevent clogging.

The result? Consistent soil moisture, less evaporation, and reduced runoff. Most growers see 30–50% water savings compared to traditional irrigation methods—while improving crop uniformity and yield.

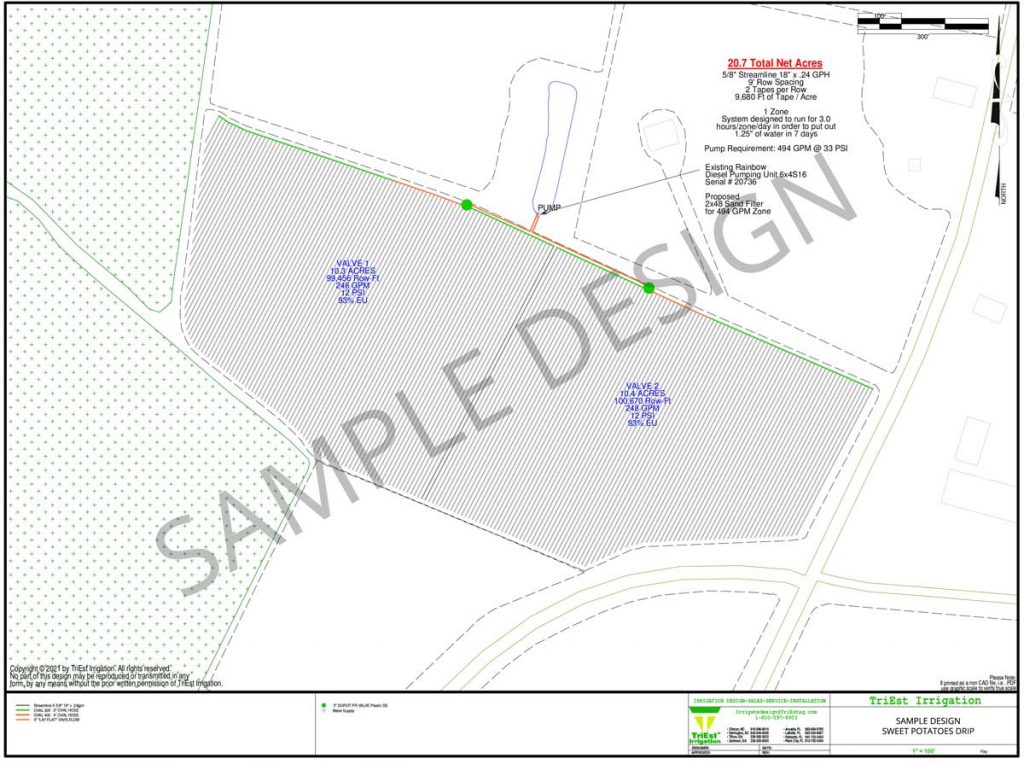

Precision Design with Smart Software

Every field has its own challenges: slope, soil type, crop spacing, and water source. Our design team utilizes software that allows them to model these factors and calculate system hydraulics before installation.

That means:

- Correct pipe sizing that considers capital cost versus long term energy cost.

- Overall design layouts that keep the grower’s system manageably in mind.

- Uniform pressure and flow to every emitter.

- A system that integrates easily with automation and fertigation.

- In short, a design that works from day one and saves money long-term.

Automation: Smarter Irrigation Management

Irrigation automation takes a grower’s control out of guesswork and into data-driven precision. Automated controllers use timers, soil moisture sensors, and climate data to irrigate only when needed.

Growers can monitor and adjust from a phone, tablet, or computer. The benefits are clear:

- Labor savings—no more walking valves across fields.

- Consistency—uniform irrigation regardless of who’s on shift.

- Better decision-making—detailed records of water use and scheduling.

- Fertigation: nutrients at the root zone.

With drip irrigation, you can do more than apply water. Fertigation injects nutrients directly into the drip system, delivering small, frequent doses right where roots can absorb them.

Advantages include:

- Reduced fertilizer use.

- Minimal nutrient loss to leaching.

- More uniform plant growth and higher quality crops.

Pumping and Filtration: The Backbone of the System

- A smart irrigation system is only as strong as its pump and filters.

- Pumping stations provide the correct pressure and flow for consistent irrigation. Many systems can be tied into automation controls for remote management.

- Filtration systems—whether it is a sand media, disc, or screen filter—are essential for clean, clog-free operation. Reliable filtration protects emitters and ensures long-term performance.

Why Quality Parts and Qualified Installers Matter

Cutting corners on irrigation rarely pays off. Low-cost parts wear out quickly, causing downtime and costly repairs. Improper installation can lead to uneven watering, wasted fertilizer, and crop stress.

Working with certified irrigation designers, trained automation installers, and trusted suppliers ensures your system is built to last and perform at peak efficiency.

The Takeaway

A smart drip irrigation system combines precision water delivery, automation, fertigation, and reliable pumping and filtration into one powerful management tool. The result: lower input costs, higher yields, and long-term sustainability.

At TriEst Ag Group, we provide growers with expert irrigation design, automation installation, and high-quality components—backed by decades of experience.

👉 Ready to upgrade your irrigation system or just learn what a well-designed irrigation system can do for your crop? Contact us HERE today.