Soil fumigation has long been a cornerstone of crop production, helping growers manage pests, disease, and weeds while giving plants the best possible start. Like all aspects of modern agriculture, fumigation has required evolution – driven by new technologies, grower needs, and a push for more efficient, targeted practices. In response to these needs and the necessity for evolution, TriEst Ag has developed a reduced-tillage fumigation system using strip-till technology.

In our last blog, we discussed the pros and cons of reducing tillage in agricultural systems and outlined our equipment suite used for the application. A quick review: the equipment used for this process is really broken down into five steps:

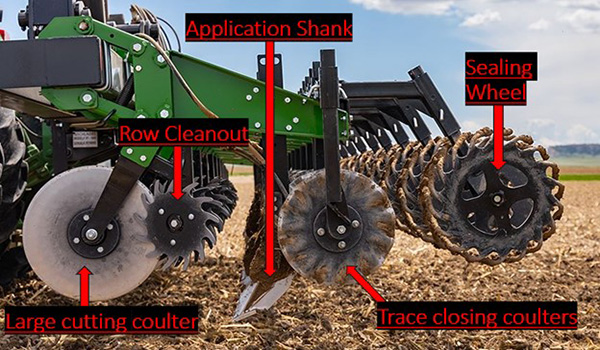

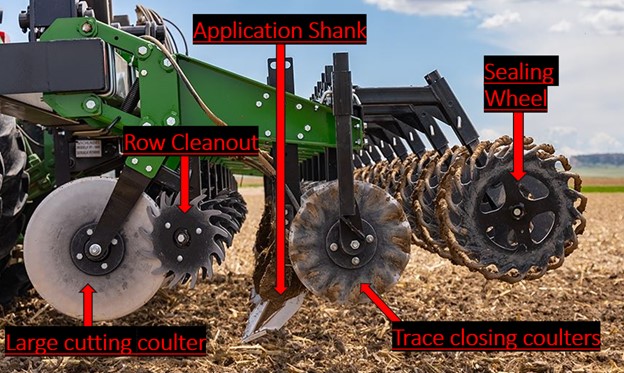

- Large straight edge coulter (cutting coulter): cuts through field debris in the center of the row.

- Notched coulter (row cleanout): grabs the cut field debris and throws it out of the strip.

- Shank: provides deep tillage to reduce compaction in the root zone while applying the fumigant product.

- Set of wavy coulters (closing discs): Pinch the soil behind the shank to shut down the chisel trace and eliminate any chimney effect.

- Compacting wheel (several options pending the desired final surface): seals the tilled area after the shank trace has been closed.

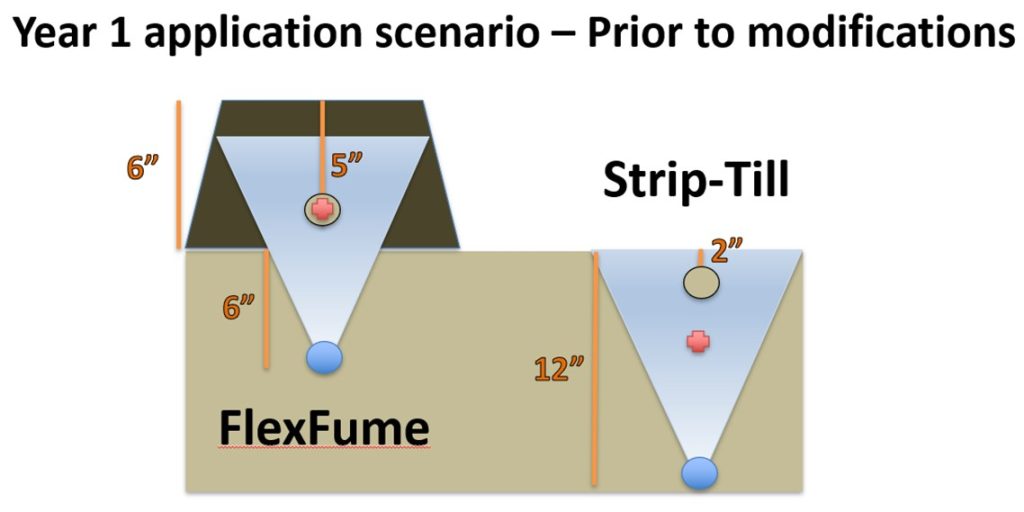

While we were pleased to have a working strip-till fumigation option, the question of efficacy remained when comparing it to grower-standard practices for applying chloropicrin-based products. In the case of the trial grower represented in this data, the standard practice was a Fall fumigation in a raised row system completed with a pressed bed (FlexFume). In the Spring prior to planting, the beds are freshened with the same fumigation rig modified with cultivators in place of the bed press (FlexTill). A pressed bed is a standard treatment for several key reasons:

- Creates a controlled environment that isolates treated soil in the bed from untreated soil in the row middles.

- Helps maintain soil fumigant concentration over time and increases efficacy.

- Warms up faster as planting approaches, creating a wider planting window.

- Allows fall-fumigated beds to be worked in the spring with limited movement of untreated soil from the middles.

- Provides flexibility in application depth due to stacking soil above the “flat” or soil-surface line.

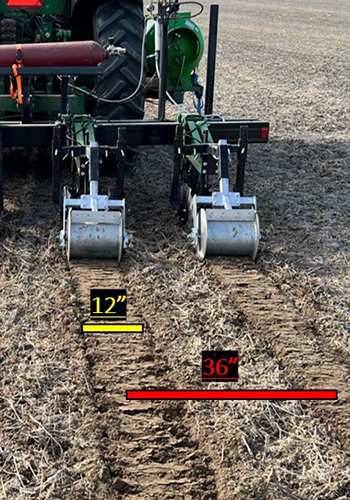

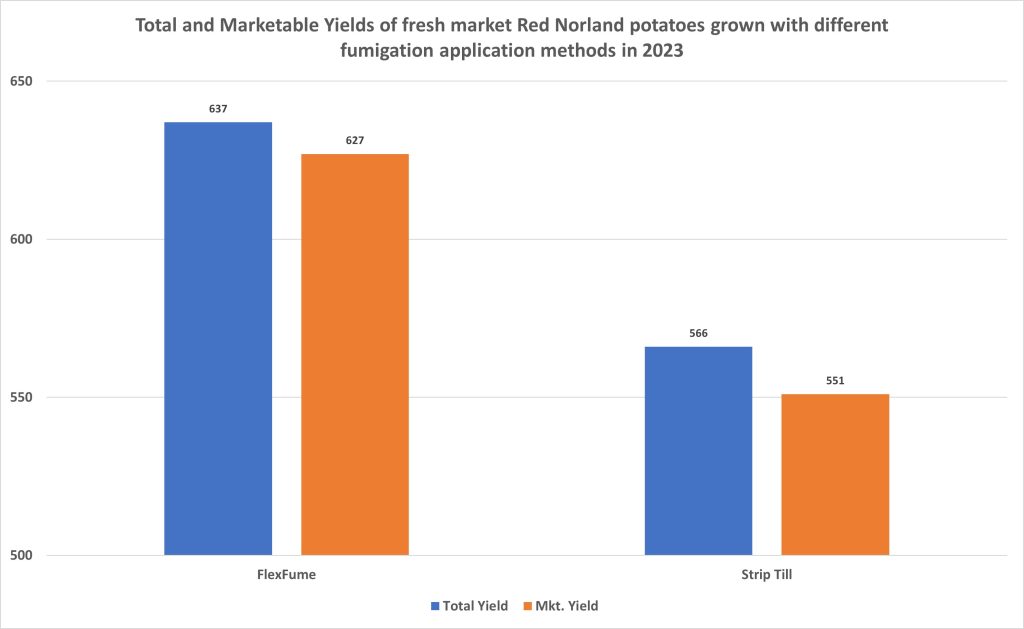

Our trial compared the raised, pressed bed system against strip-till fumigation in a side-by-side demonstration, with yields collected across six replications in each treatment. Both systems delivered 100 lbs/acre of Chloropicrin active ingredient, applied primarily for suppression of nematodes and common scab. Red Norland was the grower’s chosen variety and was sold into the fresh market.

Our key considerations when comparing these two systems were:

- Movement of untreated soil during spring tillage required for residue management prior to planting. We chose to run vertical tillage with no gain or angle on the discs, limiting side-to-side movement of soil.

- Depth of application and fumigation coverage in relation to where the potato seed piece is planted and majority of the crop is going to be produced. A label requirement of 12” from nearest soil to air interface must be met for these applications.

- Depth of planting differences between a bedded and flat potato production system. In a bedded system, the planter will open up the bed and drop a seed piece 4-5” deep into the bed and then seal the bed back together. In a flat system, the seed piece is planted shallower to reduce compaction, approximately 2”, and the planter then stacks a hill on top of the seed piece.

Year one showed promising results with good common scab suppression at less than 5%, similar to the proven grower standard. The total yield lagged behind by 71 cwt, which we believe can be improved by getting the application point closer to the seed piece. Ultimately, these results were encouraging and provide a solid framework to build upon.

In our next blog, we will cover application modifications made based on this trial and additional trial yields resulting from those changes. If you have questions or want to see results in your field you can reach out to talk to your local sales representative here.